In a refrigeration circuit, the same refrigerant fluid can work with different pressures and temperatures. This variation of conditions allows the refrigerant to change its physical state: from liquid to gas and from gas to liquid.

Working pressure’s role in the refrigeration circuit

Refrigerants are characterized by evaporating at low pressures (lower temperatures) and condensing under high pressures (higher temperatures).

With these changes, the refrigerant removes heat from within the refrigeration system (evaporator) and releases it to the external environment (condenser), thus completing the refrigeration cyclic.

To maintain the pressure difference between the high and low side, two important components come into play: the control element and the compressor.

The control element may be a capillary tube or expansion valve. It’s responsible for maintaining the pressure difference between the condenser (high pressure) and the evaporator (low pressure). By creating a resistance to the fluid flow, the control element causes the refrigerant, coming from the condenser, to go from a high pressure superheated liquid to a low pressure sub-cooled liquid, going into the evaporator.

In the evaporator, a low pressure environment, the fluid passes from a liquid state to a gaseous state, absorbing heat from the internal environment in the process.

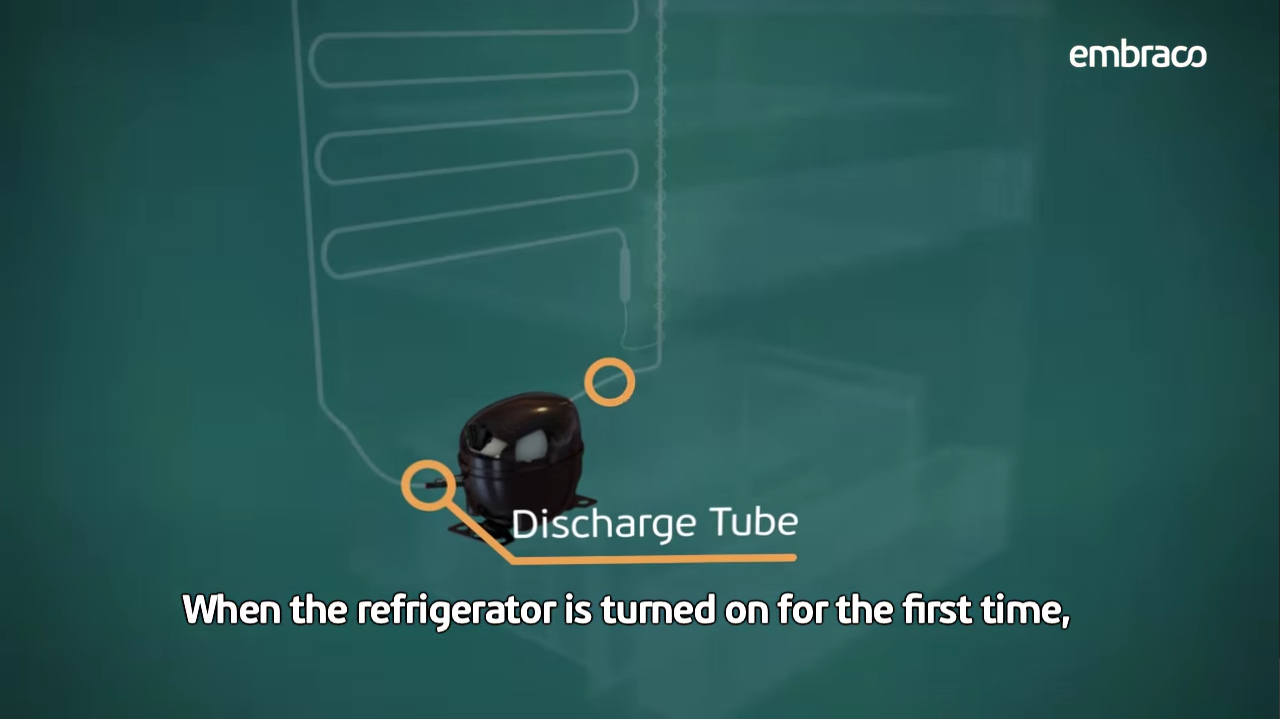

On leaving the evaporator, the refrigerant fluid is suctioned by the compressor. Then, the compressor compresses the gas, increasing both the fluid’s pressure and temperature. Afterwards, the refrigerant is pumped into the condenser. In the condenser, the fluid under high pressure releases heat to the environment and turns into a liquid. Next, the fluid passes through the filter drier and goes to the control element, continuing the cycle. Click here and see in practice how a refrigeration circuit works.

Fluids have specific working pressures

Each refrigerant fluid has specific working pressures. Most modern refrigerators have R600a fluid and the working pressure of this refrigerant is very different from that of R134a. For this reason, it’s important to pay attention when it’s time for a gas charge, avoiding excess charge.

Pressures for R600a are smaller than those of R134a. This is the contractors’ main doubt.

[box side=”alignleft” color=”box-verde” pos=”horizontal”]

Why did the R600a refrigerant replace R134a?

The first reason is associated with the thermodynamic and physical characteristics of the two refrigerants. In the compression process, R600a reaches a higher efficiency level than R134a. This means that the compressor becomes more energy efficient.

Furthermore, the R134a refrigerant is synthetic and doesn’t decompose easily in the environment. While R600a is a natural refrigerant.

Therefore, when it’s released into the environment it quickly becomes water and carbon dioxide, causing minimal impact on global warming.

When compared to R600a, R134a has 476 times greater impact on global warming. In other words, this means that each kilogram of R134a in the environment (quantity of fluid for seven domestic refrigerators) is equivalent to 476 kg of R600a (quantity of fluid for 7,933 household refrigerators). Also for not having chlorine in its composition, R600a also doesn’t cause any harm to the ozone layer. Click here and learn more about this issue.

[/box]

What to consider when doing a gas charge

Understanding the behavior and working pressures of R134a and R600a fluids is essential for servicing household refrigeration systems.

Below is a table to check the difference between the evaporation temperature and pressure for these gases:

Notice that the R134a gas works with a higher evaporation pressure than R600a.

Another important point is that they’re also used with very different charges for the same equipment. For a domestic refrigerator, R600a uses 40% to 45% of the same gas charge, when compared to R134a.

This means that there are two determining factors that should be considered: the operating pressure of R600a is lower and the refrigerant mass quantity is also smaller.

Therefore, when it’s time to do a gas charge for R600a or R134a, the contractor needs to follow the weight indicated on the refrigerator’s label and use a precision scale. As shown in the table, on the pressure gauge R600a has low negative pressures and always in lower levels than what we’re used to using with R134a. This is a working characteristic of R600a against R134a which should be interpreted as normal.